Turning Data into Solutions:

The Fuse 1+ Underdosing Project to increase number of printable polymers from 1 to 8+

Overview

Not long after we shipped the Fuse 1+, customers began reporting that their prints were “coming out wrong.” The feedback was vague, so I dug into the printer logs and ran experiments until I uncovered the root cause: one of our materials, PA11, was running on a preprint routine designed for a different powder. That mismatch starved the system at a critical moment, causing prints to fail.

Once I identified the issue, I recreated it in-house, worked with the software and design teams to adjust the process, and eliminated the failures through a tuned preprint routine. At the same time, I partnered with our Chinese manufacturers to test a mechanical agitator that would prevent powder flow problems across future materials. In the end, we delivered both an immediate fix and a long-term improvement, restoring customer trust and making the system more resilient.

It was a crash course in turning very vague customer complaints into data-driven insights, aligning teams under pressure, and delivering a solution that restored customer trust.

Customer signal → problem framing

Shortly after shipping new Fuse 1/Fuse 1+ units, support tickets spiked with prints "coming out wrong". I treated this as an incident: triaged affected printers via device logs/telemetry, interviewed customers to clarify symptoms, and clustered failures by context (location, season, material mix). Early patterns suggested environmental factors (coastal sites / summer months), so I listed humidity/temperature and material flow as top suspects and designed tests to confirm or kill those hypotheses.

Recreation of heat and humid conditions on self built rigs made by me

Hypothesis → Experiments

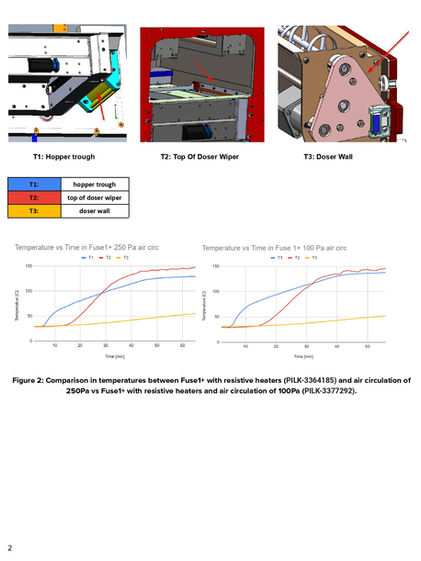

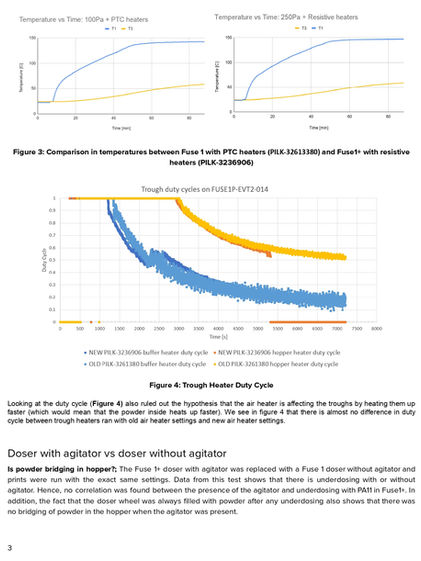

I instrumented three EVT Fuse 1+ units with thermocouples, varied air-heater types and airflow, and tracked trough/doser temperatures and duty cycles. Result: no meaningful temperature differences across the heater/airflow permutations, and no consistent correlation between ambient humidity/temperature and underdosing. That moved “environment” off the primary-cause list.

In parallel we tested powder-handling mechanics: swapped a doser with agitator for one without, varied hopper fill levels, and mixed times. Underdosing reproduced with or without an agitator and at different hopper fill states—so bridging wasn’t the proximate cause of these specific PA11 failures (even though bridging is a real issue for other powders).

Data plotted, showing no direct correlation between humidity, heat and printer fails

Root Cause (data + runs)

The breakthrough came from looking at where the system starved: whenever underdosing happened, the buffer trough was low while the doser wheel remained full, pointing to process timing rather than flow starvation. We then ran A/B tests on the preprint routines and found that using the PA12 fast preprint settings on a 50/50 PA11 mix was the key trigger. Tuning the routine (extra recoats during cold/heated precoats and rotating the doser wheel) drove underdosing to zero in our test matrix (e.g. going from 7/15 failures to 0/15 under tuned routines).

TLDR: One of the printer materials needed its own preparation process before printing. But it was running on the shortcut routine for a different material, which skipped important steps and left the machine unprepared, causing printing failures.

.jpg)

Recreation of Error inhouse

Solution Tracks

Process/software: We rolled back to the original PA11 preprint routine and defined new fast-preprint parameters for PA11 (recoat counts, sequencing, explicit priming). We also defined and documented operational KPIs (like time-to-stability and steady-state error) so we can use them to evaluate future materials and routines before rolling them out.

Hardware (robustness for future powders): While PA11’s issue was procedural, we did see bridging in several new powders. This is why, to prevent future materials from failing, I led the design of a ribbon agitator and chain-drive scheme that fits between hopper and doser, respects torque limits (<6 Nm), and fluidizes powders, targeting the evacuation of 14L of plastic powder to the bed of printer. I selected an idler/guide over a tensioner to increase wrap angle and stop chain jump in the tight envelope